Cullet Separation Device / CELVSS

Cullet Separation Device / CELVSS

“CELVSS”-Developed for cullet quality improvwment

Description

“CELVSS”stands for Ceramic Lead Vision Separation System.

A lot of foreign particles (ceramics, metals, etc) are included in cullet collected from municipal glass collection facilities. Such foreign particles cause negative effects on glass container quality and impede quality improvement in glass container production.

In 2004, Toyo Glass developed “CELVSS” using the combination of the technology accumulated for our glass inspections.

As of August 2011, a total of 15 sets of CELVSS units have been sold to Japanese cullet processing companies.

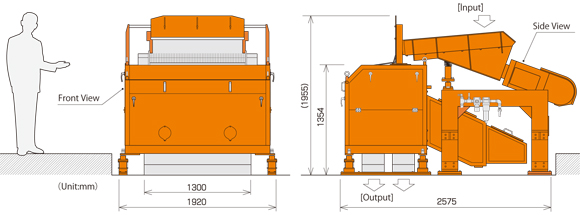

![]() Approximate Size of a CELVSS unit

Approximate Size of a CELVSS unit

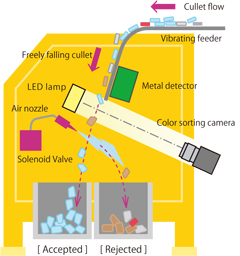

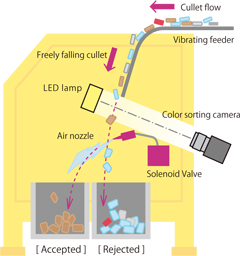

Color sorting mechanism

CELVSS consists of two functions: metal detection by a metal detector and color sorting by a color sorting camera. Cullet put into CELVSS from a vibrating feeder passes through the metal detector and then the color sorting camera. Foreign particles are rejected by a blast of compressed air.

< Foreign particle removal from single-color cullet >

Undesired colored glass and foreign particles (metals and ceramics) are rejected from single color cullet.

< Collection of a particular color cullet from mixed color cullet >

Only desired color cullet is selected from mixed color cullet. It is capable of sorting a particular color cullet regardless of whether it is transparent or opaque.

Features

The algorithm has come from the combination of the technology accumulated for the development of bottle inspection machines and devices, and our knowledge about glass compositions and properties.

It uses a white LED emitter which is more reliable and has a longer life than a fluorescent lamp.

It uses sophisticated metal detector solely developed by Toyo Glass.

It can designate a target cullet color simply by pressing a select button on the control unit.

An easy-to-use and reliable feeder is used. Its structure is so simple that undesired cullet or particle is detected and rejected as collected cullet freely falls inside the machine. The user can be assured that trouble will be prevented.