Furnace Operation Technology

Furnace Operation Technology:

Glass Homogenization and Minimizing of Bubbles.

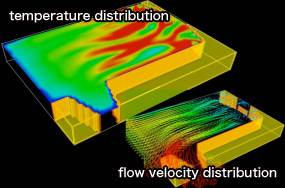

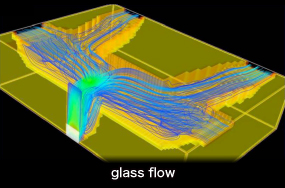

Glass melting simulation

Major raw materials of glass containers are silica sand, limestone, soda ash and cullet (recycled glass). A melting furnace that melts 150 to 200 tons of glass per day produces about 800,000 bottles to 1,000,000 bottles per day. Raw materials of glass are melted at temperature in the range of 1,500 ℃ to 1,600 ℃ and vitrified by repeated complex chemical reactions and melting. Since large quantities of gas is generated and causes bubbles in glass in the course of such chemical reactions and melting, controlling glass temperature and glass flow is necessary to reduce these bubbles and ensure glass quality. Glass temperature distribution and glass flow depend on a melting furnace structure. Toyo Glass developed numerical melting simulation models and evaluates a melting furnace design with them to ensure quality glass.