Inspection Devices

Inspection Devices

MFe(Multi-Functional eyes)

<Features>

- High-speed handling of up to 300bpm by servo-drive and out-feed device

- Capable of handling glass containers with a

Body Diameter of φ20〜φ165mm

Height of 45〜400mm

Round shape - Oval and Rectangular glass containers also can be handled when needed.

- Four standard rotating stations (up to ten can be added) and two static stations.

- One sensor for”Check” detection on a rotating station, and two sensors for “Wavy Top”, and “Height and Corkage” on two static stations are included as standard (up to ten optical sensors can be added).

- Safety-conscious with seven emergency stop buttons an overall safety cover sensors to prevent fallen glass containers from being loaded

- Less inspection lines required

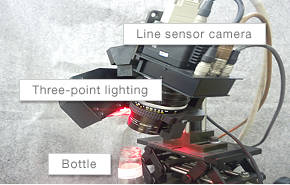

SRT Ⅳ(Sidewall Ribbon-Tear detector Ⅳ)

<Features>

- Detection of defects on the sidewall of a glass container such as

Seeds

Blisters

Ribbon Tears - Quick import of images by efficient resolution line-sensor

- Simultaneous examinations of different spheres by up to two units of cameras per handling machine

- High accuracy inspection with tall glass containers

- Easy job change, direction adjustment and focus using a line sensor camera containing an area sensor

TFG(Top Finish Gauge)

<Features>

- Simultaneous detection of defects such as:

Line Over Finish

Blistered Finish

Unfilled Finish

Overpress Finish - Imaging of reflected light from microscopic defects by a highly sensitive line sensor camera

- Sealing surface, outer edge of the sealing surface, and inner side of the finish can be illuminated using three-point lighting.

- Machine speed: MAX 250 bpm

- Mountable on an index-type handling machine which rotates each bottle

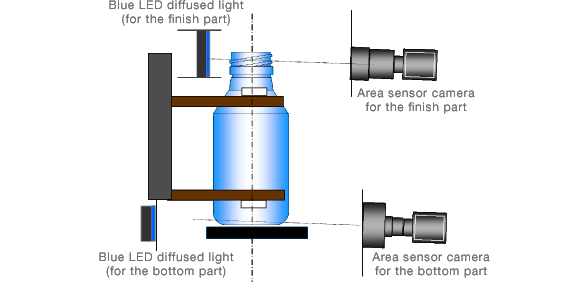

FFG Ⅱ(Finish Form Ⅱ)

<Features>

- Simultaneous inspection of items such as:

Down Sealing Surface

Skirt Diameter

Unfilled Skirt

Screw Diameter

Neck Diameter

Cocked Finish

Wavy Top

Rotation Failure

Bottle Height

Bottom Incline

Bent Neck - Dimensions of both the finish and the bottom of a glass bottle can be simultaneously inspected being illuminated by the blue LED light.

- Inspectable glass bottle size:

Outer Finish Diameter: 30mm or smaller

Body Diameter: 45mm-85mm - Machine Speed: MAX 250 bpm

- Mountable on an index-type handling machine which rotates each bottle

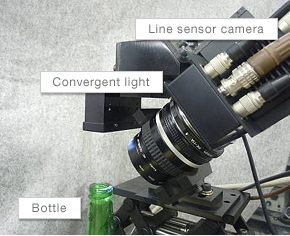

OSD(Out Step Down Detector)

<Features>

- Detection of “Overpress Guide Ring” defect

- Convergent light illuminates the guide ring (GR) of each bottle and reflected light from the GR is received by the line sensor camera

- Machine Speed: MAX 250 bpm

- Mountable on an index-type handling machine which rotates each bottle

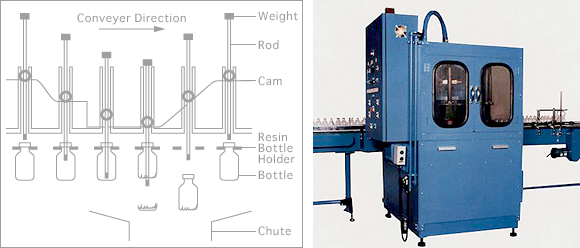

BIT(Bottom Impact Tester)

<Features>

- Simple and easy test of glass container strength by mechanical impact using a weight on the bottom of a glass container

- Inspectable glass container type:

Round-shape

Non-round shape

Outer Finish Diameter: 60φmm or less

Inner Finish Diameter: 15φmm or more

Height: 180-400mm - Machine Speed:

BIT 150: MAX 150 bpm

BIT 250: MAX 250 bpm